Small to Large Parts

At Guttenberg Industries, we excel in molding parts of all sizes, from those smaller than a dime to large components nearly 4 feet in height or width. Our expertise in producing high-quality small parts ensures dimensional precision and consistency, which are crucial for parts that fit together seamlessly.

For large parts, our U.S. domestic molding capabilities are ideal, minimizing shipping and storage costs. Since 2013, we’ve enhanced our production capacity with four new presses, enabling us to manufacture competitively priced, large-sized products using both commodity and engineering-grade materials. With a clamping force of up to 1000 tons and 15 molding machines with a tonnage of over 390, we specialize in handling larger parts with the same meticulous precision as smaller ones, maintaining our commitment to quality and volume. We have the capacity to take on your projects!

Materials - Choose From a Wide Variety!

Selecting the appropriate material for molding a part is crucial, as it directly impacts the part’s characteristics. Factors such as cosmetics, strength, size, cost, texture, and hardness must be carefully considered. Guttenberg Industries produces thousands of parts annually using a diverse range of materials, ensuring we meet various requirements.

Our expertise lies in guiding you to select the ideal resin for your project. We specialize in molding a wide array of resins, including Polypropylene (PP), Polyethylene (HDPE & LDPE), Polycarbonate (PC), ABS, TPE, Acetal, Acrylic, Polystyrene (PS), Nylon, Polyvinyl chloride (PVC), and more. By leveraging our knowledge, we can recommend the best material to optimize the performance of your parts, ensuring they meet your specific needs.

Secondary Operations

Guttenberg Industries offers a comprehensive range of assembly services, backed by extensive experience and expertise in high-quality secondary and assembly operations. Our innovative techniques provide significant labor and inventory savings compared to traditional methods.

We handle everything from simple operations to complete assemblies in consumer-ready packaging, shipped directly to your specified destination. Whether you need intricate component assembly or fully packaged products, we ensure the fastest and most efficient service possible. Let us streamline your manufacturing process with our advanced assembly solutions, optimizing both efficiency and cost-effectiveness.

Quality & Communication

We are renowned for our problem-solving capabilities and exceptional quality. We achieve high-quality standards through communication, cooperation, careful planning, and excellent manufacturing practices.

Our formal quality recognition began in 1997 with ISO 9002 registration, transitioning to ISO 9001 three years later, and renewing to ISO 9001:2015 in 2022.

Our quality system is designed to understand and meet customer needs, validate processes, and continually improve cost, consistency, and customer satisfaction.

Each product we make follows a customized quality plan with step-by-step production instructions and pictures. The process starts before production, with sampling and approval stages to meet customer specifications.

Automation for Cost Savings

We utilize robotics from simple sprue pickers to full-service 6-axis robots. We also custom-design, program, and build automation for high-efficiency production. We invest in on-going research and development for continuous improvement for our company and our customers.

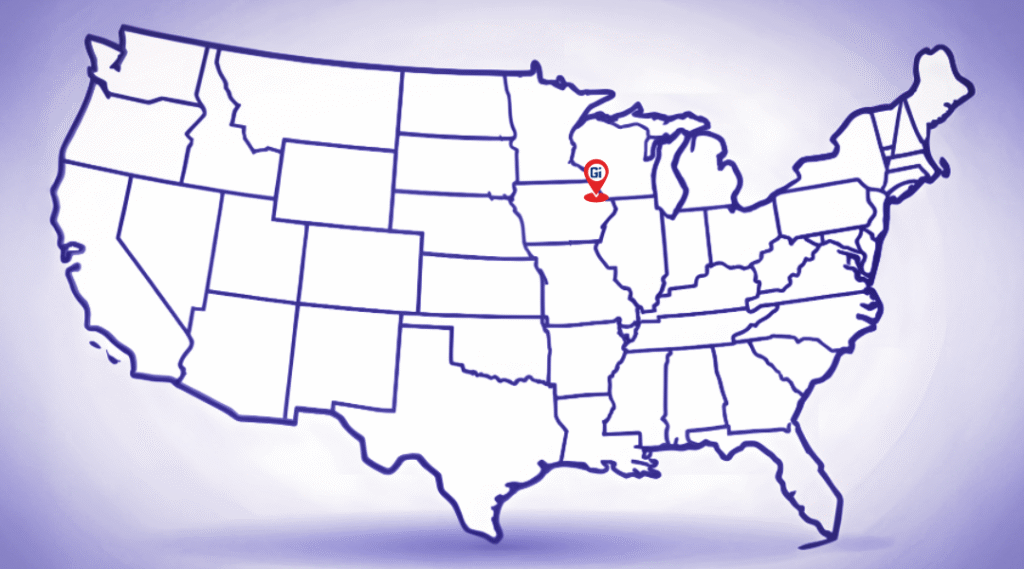

Find Us Here!

Located in Northeast Iowa, we are conveniently positioned between Chicago and Omaha, as well as Minneapolis/St. Paul and St. Louis. This prime Midwest location allows us to offer economical shipping on major truck routes delivering throughout the U.S., Canada and Mexico.

Guttenberg Industries, Inc.

P.O. Box 70

603 S. Lincoln St.

Garnavillo, IA 52049

Shipping & Receiving

601 S. Lincoln St.,

Garnavillo, IA 52049

- ISO 9001:2015

- TS 16949 Compliant

- PPAP & APQP for ALL parts