Quality Begins at Day One!

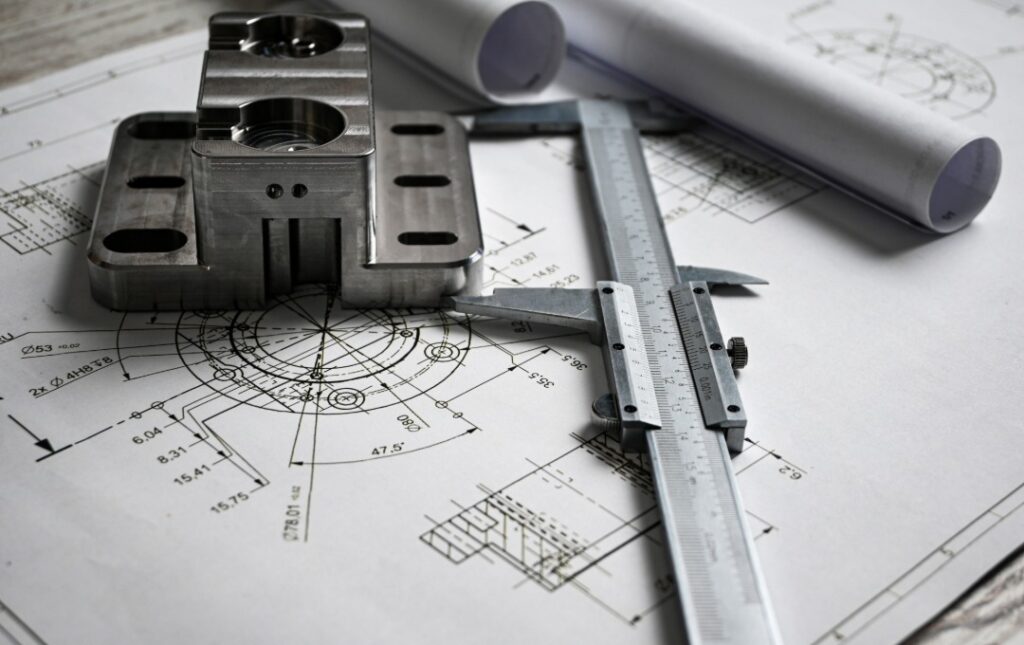

Engineering Support

Before the tool design is finalized, our engineers collaborate with your team to review the part design for potential material savings, cycle time reductions, and quality enhancements. We adhere to and implement the Society for Plastics Industry (SPI) guidelines and standards for Mold Classes, Mold Finish, Cosmetic Inspection, and Dimensional Tolerances.

Additionally, we offer options and recommendations for selecting tool-builders to quote your project. Guttenberg Industries is privileged to work with several local and regional tool shops renowned for their quality molds. In addition, for the past decade, we have provided our customers with the option to utilize our carefully selected offshore partners for injection mold construction. Ultimately, it will be our customer’s decision on which source they’d like to use.

Product Development Lead Time

In today’s competitive landscape, time to market is crucial. The faster you can introduce your product to the market, the sooner you can start generating returns on your investments. At Guttenberg Industries, we recognize this imperative and consistently strive to help you reduce this timeframe. We employ rapid prototype services where applicable and offer quick turn-around tooling upon request. Please inform us if you are interested in exploring these options.

Material Selection

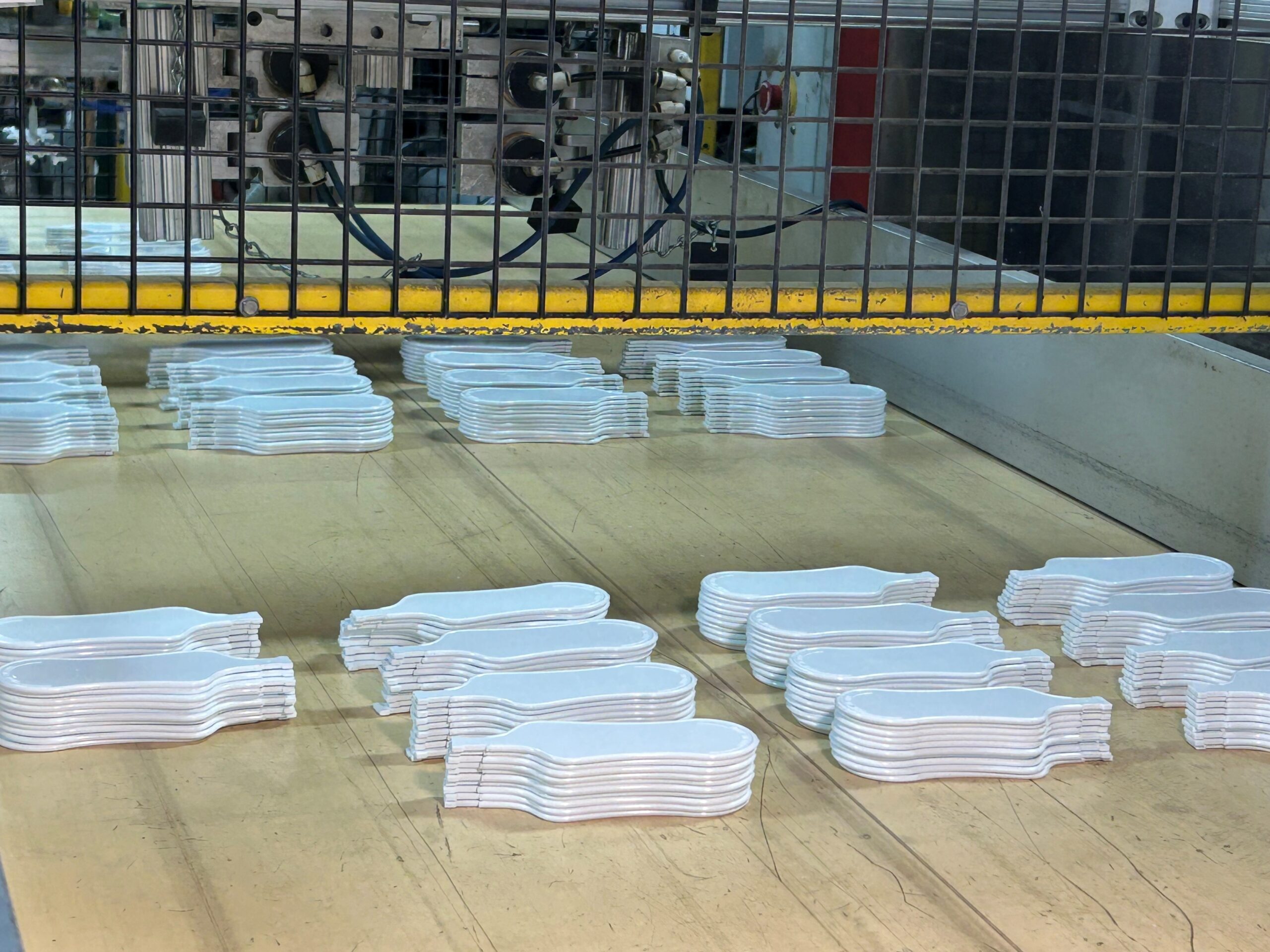

Designing injection molded plastic parts can be complex and confusing. The task of designing any material is already quite complex, but with injection molded plastic that complexity is compounded further due to the nature of plastics and the molding process. Guttenberg Industries has built a solid reputation within the injection molding industry for our ability to conquer the toughest jobs in plastic.

In many instances, the first decision that needs to be determined is which material to use. Thanks to technology, there are literally hundreds of materials and blends that may work for your project. However, when designing a plastic part, material selection is critical. There are a lot of things to consider when choosing a material, such as strength, hardness, impact resistance, heat resistance, chemical resistance, and cost.

Design Tolerances

Tolerance guidelines are expressed as a base (minimum) tolerance plus added tolerance based on linear inch of a given product feature, and represent typical variation from part to part once molded. By means of example, a two-inch feature on a product molded from ABS will likely consume a tolerance of +/- .005 inches while the same feature on a part molded from Polypropylene might consume a tolerance of +/- .007 inches.

Project Costs

Consider the Total Cost of Ownership, Not Just Price.

When designing injection molded plastic products, there are two types of cost to consider. The first is the piece part cost. This is the amount of money you will pay the injection molder for each piece you have them mold. The second type of cost is tooling cost.

Unfortunately, not all customers fully consider this trade-off relationship when finalizing their purchase decision. In many cases, the customer is focused heavily on piece price and ends up buying a more expensive tool than is necessary, ultimately paying too much once the tool price is factored in. In other cases, the customer focuses heavily on getting an inexpensive tool and builds a single cavity tool to save money in the short-term but costs more over time.

Part Design Suggestions

Our review of part design begins during the quoting stage. Our experienced estimating team is skilled in detecting product features that add cost and risk downstream quality problems. If we think we can save you money, suggestions are often provided during this phase.

Otherwise, a more detailed analysis is performed by a team of experts during the early hours of the product launch. This team actively searches for cost-saving opportunities and design features that might create a risk of problems later in the process. MoldFlow simulation software is used to detect potential problems, maximizing the potential for first-round success. Any ideas are communicated to you right away so that you may update the design quickly if you decide to do so. And if you don’t choose to act on our suggestions, that is fine. But we will keep trying to help in any way we can.

We now even provide free online assistance with an 11-page PDF that highlights 10 design tips for injection molded parts/products as well as insights on plastic materials and tolerances.

Design for Manufacturability (DFM)

Design for Manufacturability, or DFM, is a time-tested tool to help product designers minimize costs and time to market. Complex designs incur additional costs. Sometimes complexity is necessary. However, unnecessarily complex plastic injection molding designs can increase the manufacturing costs of plastic parts significantly. Our professional staff at Guttenberg Industries aims to help you use DFM in order to keep your designs as simple as possible while keeping costs to a minimum.

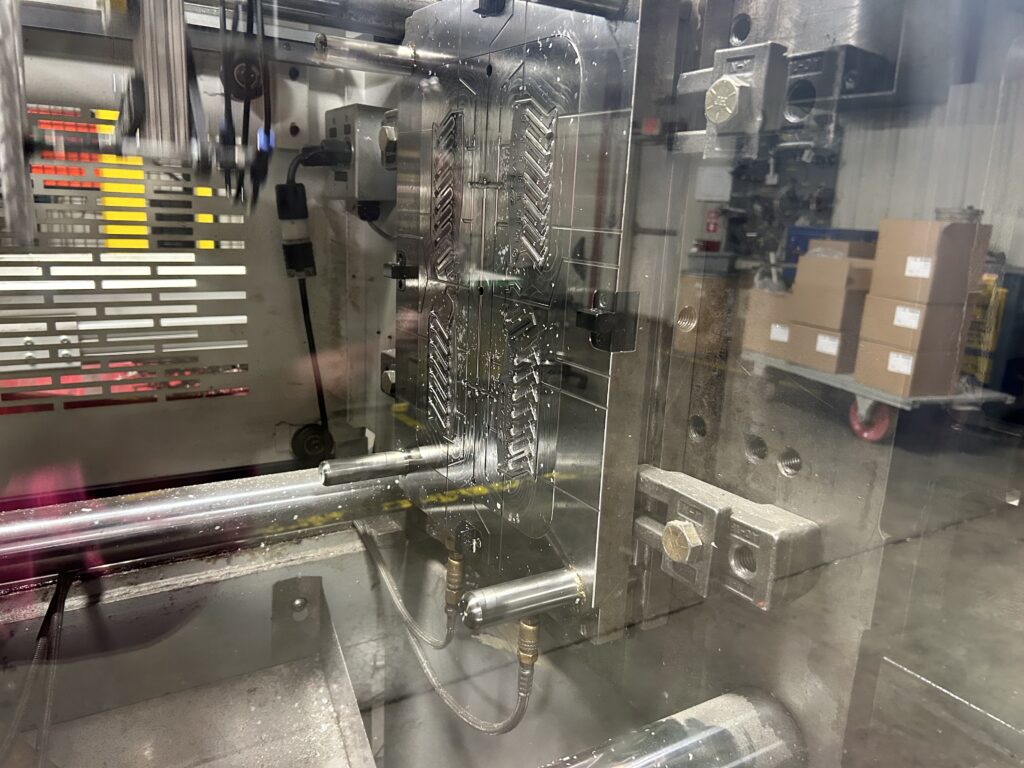

Mold Design Suggestions

Guttenberg Industries offers customers the option of domestic or offshore tool builds, with complete oversight and production of parts manufactured in our Iowa facility.

Tool designs are developed by toolmakers based on the CAD models provided by Guttenberg Industries on the behalf of you, the customer. Before any actual tool work is begun, the tool design must be approved by Guttenberg Industries. Improper tool design can lead to quality problems, increased production costs, and limited tool life. To minimize the risk, our team of experts reviews each tool design with a point checklist, ensuring the highest quality tool for your money.

We coordinate the tool build and offer weekly progress updates upon request. We work with your engineers and quality professionals to ensure we understand your unique quality requirements before the mold is even complete. When the mold is complete, we sample the mold to verify it meets your requirements and tweak the mold or process until it does.

And, if you are transferring a tool from another molder, we still do all of the same, except for the tool build.

How Does Guttenberg Industries Ensure Quality Products?

Keyence XM Series: This hand-held Coordinate Measuring Machine (CMM) offers versatile measurements from points inaccessible to traditional Bridge CMMs and vision-guided machines. It provides highly accurate measurements within ±3 microns. The measurement area is 23.62” wide by 14.96” tall, accommodating large parts. The XM Series uses advanced algorithms to ensure precision and is user-friendly, requiring minimal training.

Keyence IM Series: An optical comparator capable of measuring multiple dimensions across several parts simultaneously. It features a high-resolution camera and a light probe for touch measurements, both with 2-micron accuracy. The IM Series is designed for quick, consistent measurements with a simple push-button operation once programmed. It integrates advanced image processing technology to enhance measurement reliability.

Our inspection equipment includes additional video inspection machines, a wide range of classic handheld instruments, and numerous checking fixtures. Every member of our quality assurance staff is also a hands-on expert in production, ensuring that all measurements and inspections meet stringent quality standards.

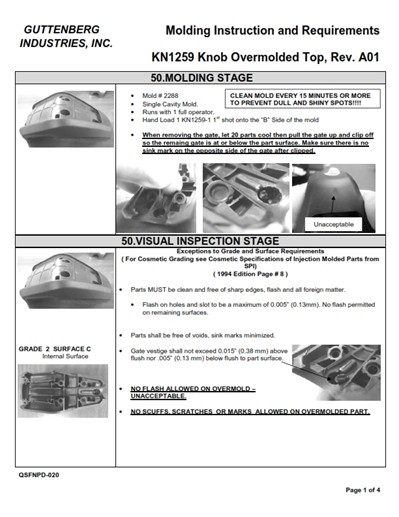

Molding Instructions & Requirements

Our team is here to ensure quality at every step of our process. Getting started is simple! We will follow your Molding Instruction Requirements (MIR): digital photographs, visual and dimensional acceptance criteria, and product-specific key characteristics and concerns. We encourage customers to specify the functional and cosmetic characteristics of each part.

Our quality assurance team operates 24/5, conducting routine cosmetic and dimensional inspections. We can measure any measurable attribute, with most instruments featuring data ports for easy data collection and analysis.

We utilize Statistical Process Control software to monitor and detect out-of-specification conditions before they become out-of-tolerance.

Your quality requirements are communicated clearly and diligently throughout our organization, integral to our ISO certification and our commitment to superior customer satisfaction with high-quality parts.

Discover how we can integrate quality into your process.

Guttenberg Industries, Inc.

P.O. Box 70

603 S. Lincoln St.

Garnavillo, IA 52049

Shipping & Receiving

601 S. Lincoln St.,

Garnavillo, IA 52049

- ISO 9001:2015

- TS 16949 Compliant

- PPAP & APQP for ALL parts